PRODUCT DISPLAY

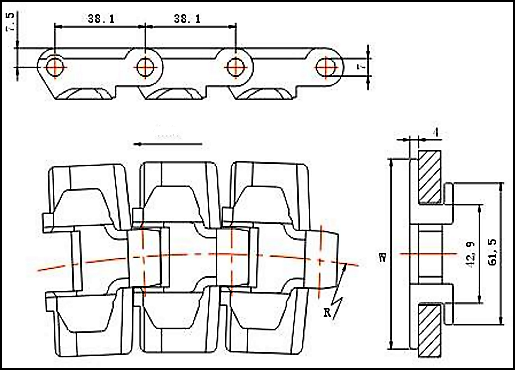

C880T Table Top Chain

Key words:

socket

technology

32A

Category:

At Guangzhou Sinoda Intelligent Equipment Co., Ltd., we are dedicated to providing innovative and high-quality conveyor solutions. With over 20 years of experience in the industry, our expertise spans mold development, material application, and extrusion molding. Our commitment to independent research and development has led us to build a highly skilled R&D team, ensuring that our products meet the highest standards of performance and reliability.

Product Highlight: Table Top Chain

Durable and Reliable Performance

The Table Top Chain is designed to deliver exceptional durability and reliability. Constructed from high-quality materials, this chain is built to withstand the rigors of continuous operation, ensuring a long service life and minimal downtime. Its robust construction makes it an ideal choice for demanding industrial environments.

Smooth and Precise Movement

The Table Top Chain is known for its smooth and precise movement, making it perfect for assembly lines, packaging, and sorting applications. The chain's design ensures that products move steadily and accurately, reducing the risk of damage and improving overall efficiency.

Versatile Applications

The Table Top Chain is highly versatile and can be used in a wide range of industries. From food and beverage to automotive, pharmaceutical cosmetics, and warehousing and logistics, this chain is designed to meet the diverse needs of modern conveyor systems. Its flexibility and adaptability make it an excellent choice for both straight and curved conveying applications.

Easy to Clean and Maintain

Maintaining a hygienic environment is crucial in many industries, and the Table Top Chain is designed with this in mind. The smooth surface and easy-to-clean design reduce the risk of contamination and ensure that your production line remains sanitary. This feature is particularly beneficial in food processing and pharmaceutical applications where cleanliness is paramount.

Customized Solutions

At Sinoda, we understand that every customer has unique requirements. That's why we offer customized solutions to meet your specific needs. Our experienced R&D team works closely with you to develop conveyor systems that integrate seamlessly into your existing operations. Whether you need a standard Table Top Chain or a custom-designed solution, we have the expertise to deliver.

Global Reach and Support

With a global layout and a strong commitment to customer service, Sinoda's products are exported to countries such as the United States, Indonesia, Vietnam, Turkey, Brazil, and more. Our efficient warehousing and logistics distribution systems, combined with our global marketing service networks, ensure that you receive the support you need, wherever you are in the world.

Tabletop Chain Conveyor Solutions

Our Tabletop Chain Conveyor systems are designed to provide seamless and efficient material handling. These conveyors are ideal for a variety of applications, including:

- Assembly Lines: Ensure smooth and precise movement of components and finished products.

- Packaging: Facilitate the packaging process with reliable and consistent performance.

- Sorting: Efficiently sort and transport items in various industries, from e-commerce to pharmaceuticals.

Table Top Chain Manufacturers and Table Top Chain Conveyor Manufacturers

As a leading Table Top Chain Manufacturers and Table Top Chain Conveyor Manufacturers, Sinoda is committed to delivering top-quality products that meet the highest industry standards. Our Table Top Chain and Tabletop Chain Conveyor systems are designed to be durable, reliable, and easy to maintain, ensuring that they provide long-term value to our customers.

To learn more about our Table Top Chain and how it can enhance your conveyor system, please contact us!

|

Chain data |

||||

|

Part number |

Chain width mm |

Chain weight kg/m |

Chain material |

Nominal tensile strength straight run N/M (21°C) |

|

C880T0325 |

82.6 |

0.95 |

POM |

2250 |

|

C880T0450 |

114.3 |

1.10 |

||

Remark:

● The nominal tensile strength is valid for 21 °C (70 °F). The admissible tensile force depends on the operating temperature near the drive sprockets.

● The weight specification is indicative.

Disclaimer:

Product Application Disclaimer (valid for ALL Path conveyor products and mentioned on all PDS)

This disclaimer is made by and on behalf of Path conveyor and its affiliated companies, directors, employees, agents and contractors (hereinafter collectively "Path conveyor") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Path conveyor catalogue as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness, accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY PATH CONVEYOR, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS".

Previous page

Next page

Related products

undefined

MESSAGE

* Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible