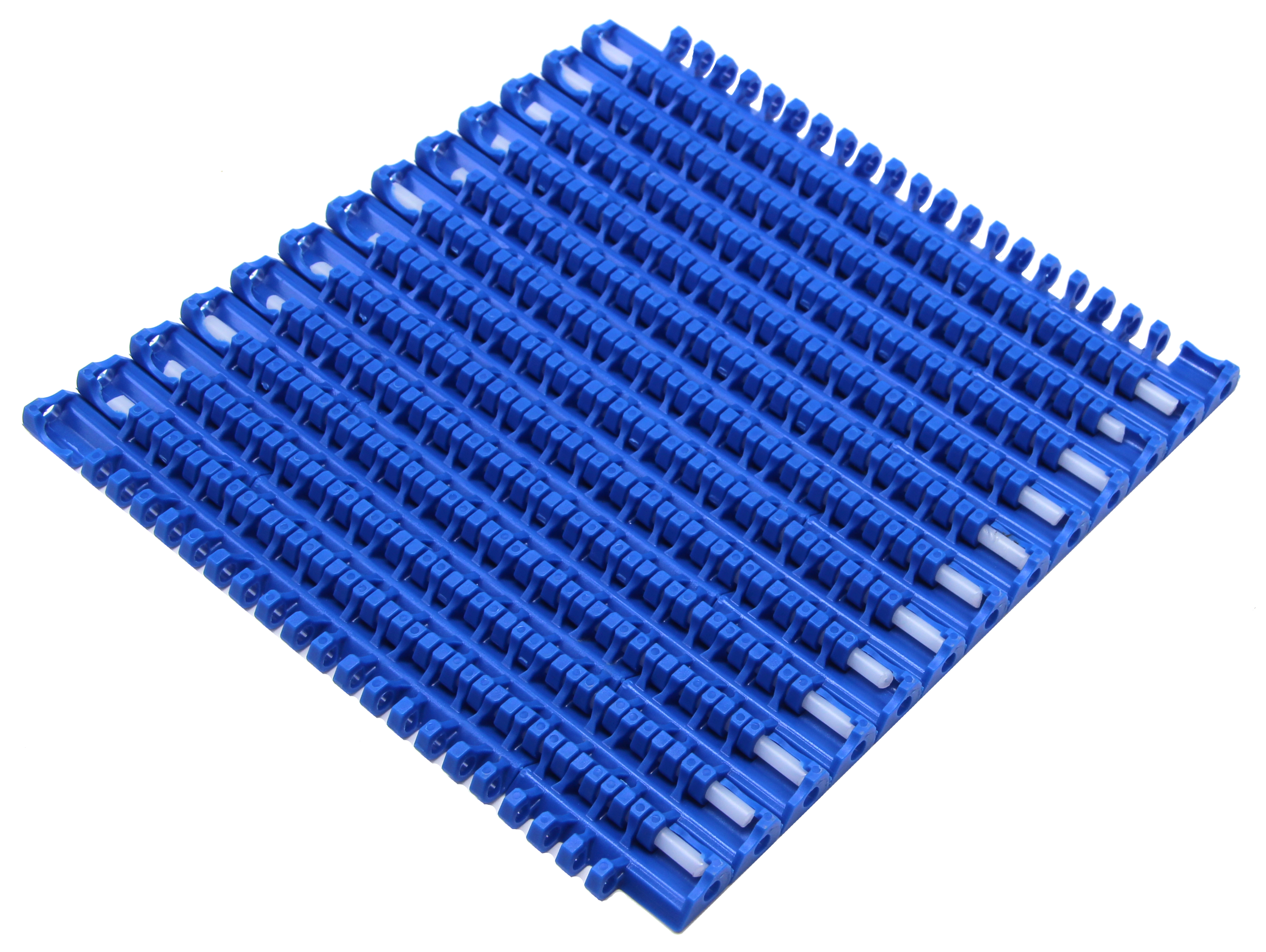

PRODUCT DISPLAY

M1100 Flat top Modular Belt

Key words:

socket

technology

32A

Category:

Features of Flat top Modular Belt

● Lightweight with smooth, closed surface grid.

The Flat Top Modular Belt is distinguished by its lightweight construction combined with a smooth, closed surface grid. This design feature significantly enhances the belt's performance across various applications. The lightweight nature of the belt reduces the overall strain on conveyor systems, leading to lower energy consumption and reduced wear on components such as bearings and motors. Moreover, the reduced weight minimizes the impact forces experienced during operation, contributing to quieter and smoother running conditions.

The smooth, closed surface grid ensures that products glide effortlessly over the belt without the risk of snagging or damage. This is particularly advantageous in industries where delicate items are handled, such as food processing, electronics manufacturing, and pharmaceuticals. The closed surface also prevents small particles from penetrating the belt structure, which not only maintains product integrity but also simplifies cleaning processes. In environments where hygiene standards are stringent, such as in medical device production or cleanroom operations, this characteristic is invaluable for ensuring contamination-free conveyance.

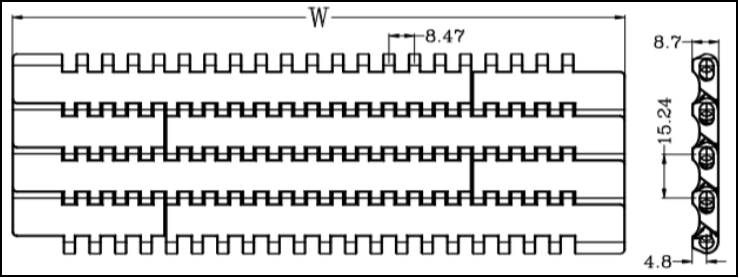

● Small pitch reduces chordal action and the gap required at the transfer dead plate.

A notable advantage of the Flat Top Modular Belt is its small pitch design, which plays a critical role in reducing chordal action and minimizing the gap required at the transfer dead plate. Chordal action, or chordal effect, refers to the slight up-and-down motion that can occur as the belt moves around pulleys or sprockets. By employing a smaller pitch, the belt effectively diminishes this effect, resulting in more stable and precise product movement. This stability is crucial for maintaining accurate positioning of items during conveyance, especially in high-speed lines where even minor deviations can lead to significant issues.

Additionally, the minimized gap at the transfer dead plate—the point where the belt transfers from one section of the conveyor to another—greatly improves operational efficiency. A smaller gap reduces the likelihood of product misalignment or loss during transfer, thereby increasing throughput and reducing downtime for adjustments or retrieval. It also allows for tighter radius turns, making it possible to configure conveyors in compact spaces without compromising on performance. This flexibility in layout design can be a significant benefit for manufacturers looking to optimize their factory floor space while enhancing productivity.

● Contact Path Conveyor for precise belt measurements and stock status before designing equipment or ordering a belt.

|

Belt data |

||||

|

Belt material |

Rod material |

Nominal tensile strength straight run N/M (21°C) |

Belt weight kg/m² |

Standard range of belt widths mm |

|

POM |

PP |

14000 |

6.35 |

203.2+152.4*n |

|

PE |

12000 |

6.35 |

||

|

PP |

PP |

9000 |

4.40 |

|

|

PE |

PE |

7000 |

4.69 |

|

|

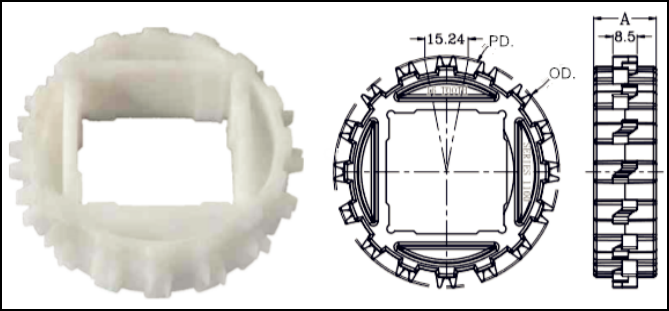

Sprocket data |

|||||||

|

Part number |

No.of Teeth |

Bore Dia.mm |

Pitch Dia. mm |

Outside Dia. mm |

Processing Technic |

Material |

|

|

Round Bore |

Square Bore |

||||||

|

SP-1100-16T |

16 |

25/30 |

40 |

78.12 |

79.40 |

Injection molding |

POM/PP/PA |

|

SP-1100-32T |

32 |

30/40 |

40/50 |

155.48 |

156.50 |

||

Remark:

Real belt widths are in most cases 0.1% to 0.3% smaller.

For PE material up to 750 mm (30") -2 mm to 1 mm and -0.3% to 0.1% for wider belts.

For PP material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

For POM material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

The nominal tensile strength is valid for 21 °C. The admissible tensile force depends on the operating temperature near the drive sprockets. Within the temperature range allowed, the admissible tensile force may vary from 100% to 20% of the nominal tensile strength.

Disclaimer:

Product Application Disclaimer (valid for ALL Path conveyor products and mentioned on all PDS)

This disclaimer is made by and on behalf of Path conveyor and its affiliated companies, directors, employees, agents and contractors (hereinafter collectively "Path conveyor") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Path conveyor catalogue as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness, accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY PATH CONVEYOR, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS".

Previous page

Next page

Related products

undefined

MESSAGE

* Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible