PRODUCT DISPLAY

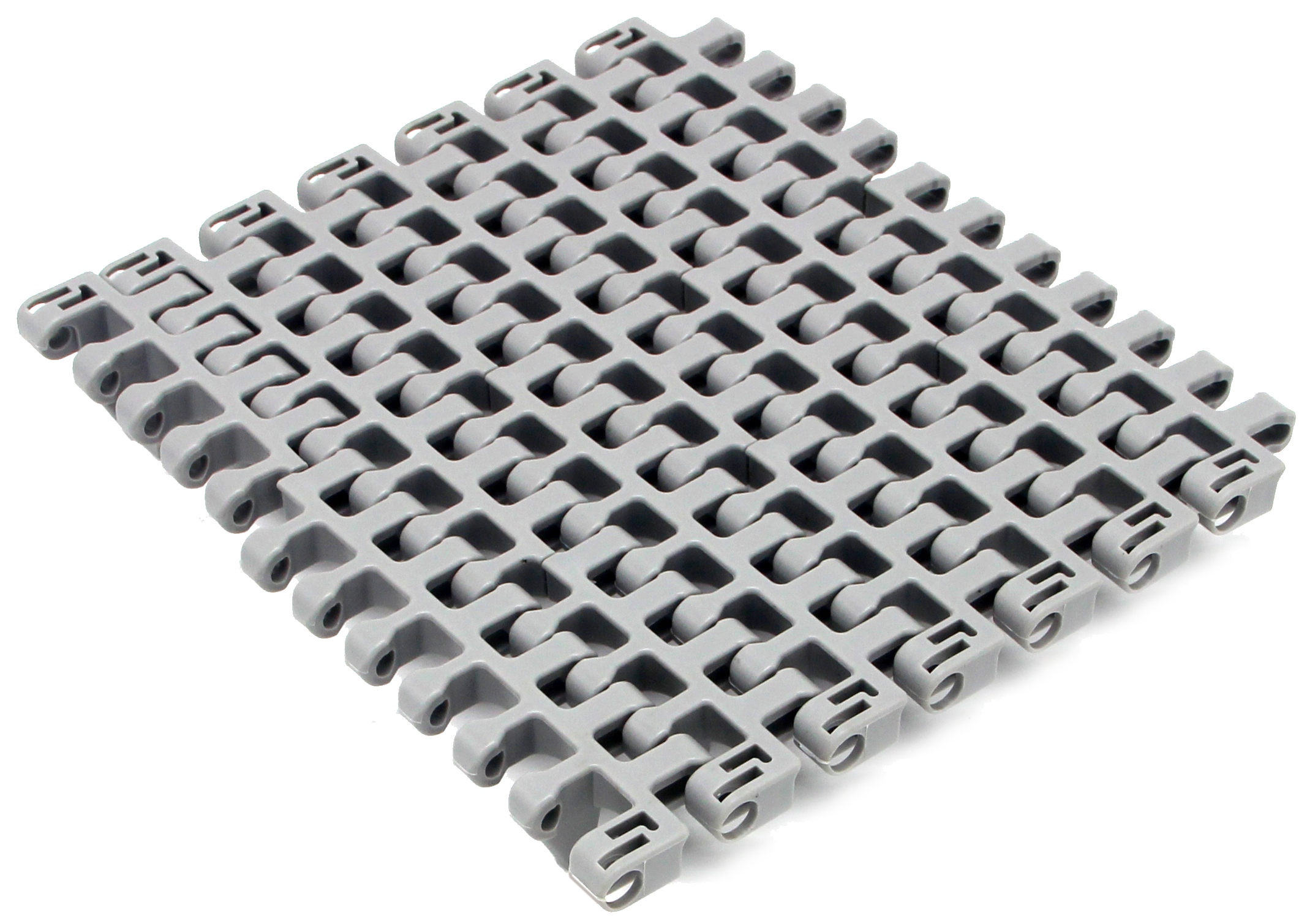

M2540 Radius Flush Grid Modular Belt

Key words:

socket

technology

32A

Category:

Features

● For radius and straight conveying (collapse factor 2.2).

The Radius Flush Grid Modular Belt is designed to excel in both straight and curved conveying applications, thanks to its collapse factor of 2.2. This allows the belt to navigate tight turns smoothly while maintaining stability and product alignment, making it highly versatile for a variety of conveyor systems.

● 53% open contact area; largest opening 6x12.5 mm (0.24"x0.49").

With a 53% open contact area and the largest opening measuring 6x12.5 mm (0.24"x0.49"), this belt offers excellent surface coverage while allowing for efficient drainage and air circulation. The optimized open area ensures that the belt can handle a wide range of products, from small parts to larger items, without compromising performance.

● Excellent for cooling and draining.

The Flush Grid Modular Belt is particularly well-suited for applications that require effective cooling and draining. The open grid design facilitates rapid heat dissipation and water drainage, making it ideal for food processing, pharmaceuticals, and other industries where hygiene and temperature control are critical.

● Easy to clean.

Maintenance is simplified with the Radius Flush Grid Modular Belt. The open grid design and smooth surface make it easy to clean, reducing downtime and ensuring a hygienic environment. This is especially beneficial in industries where regular cleaning is necessary to maintain high standards of sanitation.

● Contact Path Conveyor for precise belt measurements and stock status before designing equipment or ordering a belt.

To ensure the best fit and performance, we recommend contacting Path Conveyor for precise belt measurements and stock status. This ensures that the belt you order is perfectly suited to your specific equipment and application, minimizing the risk of errors and delays in your operations.

|

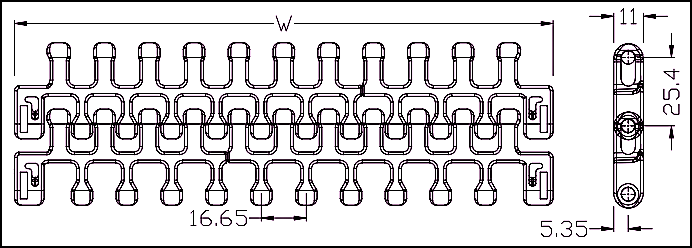

Belt data |

||||

|

Belt material |

Rod material |

Nominal tensile strength straight run N/M (21°C) |

Belt weight kg/m² |

Standard range of belt widths mm |

|

POM |

PP |

25000 |

6.90 |

200+100*n |

|

PA |

27000 |

7.00 |

||

|

PP |

PP |

19000 |

4.70 |

|

|

PA |

PA |

25000 |

6.00 |

|

|

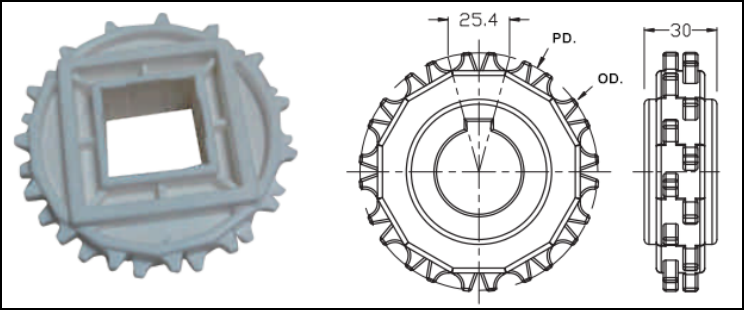

Sprocket data |

|||||||

|

Part number |

No.of Teeth |

Bore Dia.mm |

Pitch Dia. mm |

Outside Dia. mm |

Processing Technic |

Material |

|

|

Round Bore |

Square Bore |

||||||

|

SP-2540-12T |

12 |

30/35 |

40 |

98.14 |

99 |

Injection |

POM/PA/PP |

|

SP-2540-15T |

15 |

30/40 |

40/65 |

122.17 |

123 |

Injection |

POM/PA/PP |

|

SP-2540-20T |

20 |

|

50 |

163 |

164 |

Injection |

POM/PA/PP |

Remark:

Real belt widths are in most cases 0.1% to 0.3% smaller.

For PE material up to 750 mm (30") -2 mm to 1 mm and -0.3% to 0.1% for wider belts.

For PP material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

For POM material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

The nominal tensile strength is valid for 21 °C. The admissible tensile force depends on the operating temperature near the drive sprockets. Within the temperature range allowed, the admissible tensile force may vary from 100% to 20% of the nominal tensile strength.

Disclaimer:

Product Application Disclaimer (valid for ALL Path conveyor products and mentioned on all PDS)

This disclaimer is made by and on behalf of Path conveyor and its affiliated companies, directors, employees, agents and contractors (hereinafter collectively "Path conveyor") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Path conveyor catalogue as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness, accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY PATH CONVEYOR, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS".

Previous page

Next page

Related products

undefined

MESSAGE

* Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible