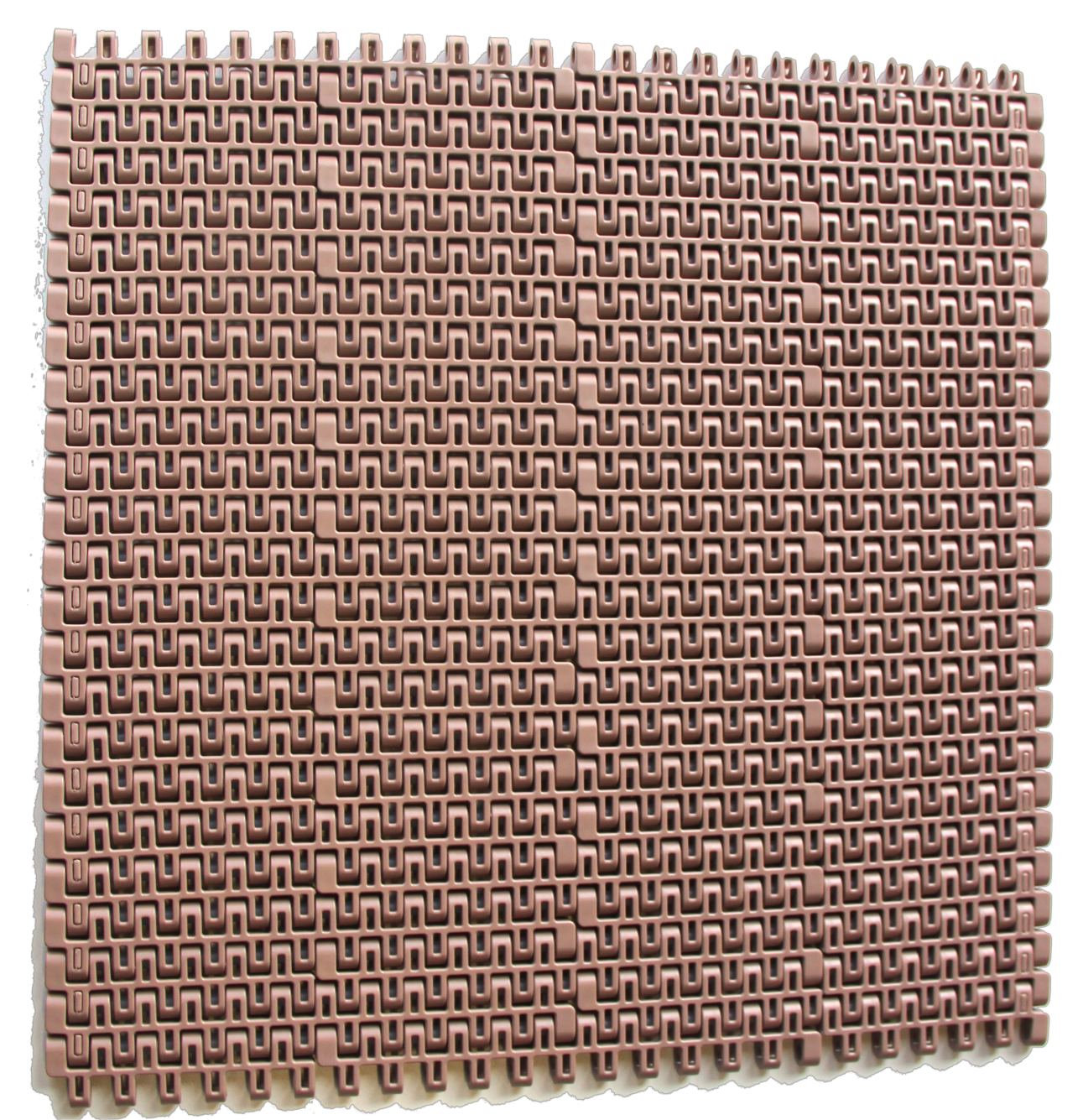

PRODUCT DISPLAY

SNB M2 14 Mesh Top Modular Belt

Key words:

socket

technology

32A

Category:

Mesh Top Modular Belt Solution

The Mesh Top Modular Belt Solution represents an advanced approach to conveying systems, tailored for industries demanding precision and reliability in their material handling processes. Crafted from high-quality engineering polymers, this modular belt is designed to withstand the rigors of continuous operation while offering excellent chemical resistance and easy cleanability. Its mesh top design ensures optimal product support and drainage, making it ideal for applications that require water or particulate matter to pass through the belt, such as in food processing, packaging, and bottling lines.

The versatility of the Mesh Top Modular Belt lies in its modularity; the belt can be configured to fit a wide range of conveyor widths and layouts, adapting effortlessly to straight runs, curves, and inclines. This adaptability, combined with quick-release features for easy maintenance and replacement, minimizes downtime and maximizes efficiency on the production floor. Furthermore, the belt's open-area construction reduces product contact surface area, which can lead to improved hygiene standards and reduced risk of contamination.

Engineered for performance, the Mesh Top Modular Belt also supports high-speed operations without compromising on durability or safety. It offers a robust solution for manufacturers seeking to enhance productivity and ensure smooth, uninterrupted production flows in challenging environments.

The Mesh Top Modular Belt is widely utilized across various industries for its versatile performance and adaptability, offering a range of applications that cater to specific processing needs. Here are some key applications where this type of belt excels:

Food Processing: The open mesh design facilitates excellent drainage, making it ideal for washing, rinsing, and drying processes. It allows water, cleaning solutions, or small debris to pass through while securely conveying the product. This is particularly beneficial in applications like fruit and vegetable processing, poultry handling, and seafood preparation.

Baking Industry: In bakeries, the belt's heat resistance and ability to handle delicate products make it suitable for proofing, baking, and cooling lines. Its non-stick properties prevent dough from adhering to the surface, ensuring smooth transfer without damaging the product.

Packaging and Bottling Lines: The precise control over product placement and movement makes the mesh top modular belt perfect for packaging and bottling operations. Whether conveying lightweight plastic bottles or heavier glass containers, the belt ensures stable transport and accurate positioning.

Pharmaceutical Manufacturing: For pharmaceuticals, hygiene is paramount. The ease of cleaning and sterilizing the mesh top modular belt helps maintain strict sanitation standards required in this industry. It can be used in tablet manufacturing, packaging, and other cleanroom applications.

Agricultural Product Handling: From sorting and grading to packing agricultural produce, the belt's durability and ability to withstand outdoor elements make it a reliable choice for farm-to-market operations.

Freezing and Cooling Applications: Designed to endure low temperatures, the mesh top modular belt performs efficiently in freezing tunnels and chillers. Its structure prevents icing, ensuring consistent performance even under cold conditions.

Confectionery Production: In confectionery, the belt supports the gentle handling of candies, chocolates, and other sweets during production, cooling, and packaging stages.

Recycling and Waste Management: For sorting and processing recyclable materials, the belt's robust construction and open design allow for efficient material flow and separation.

|

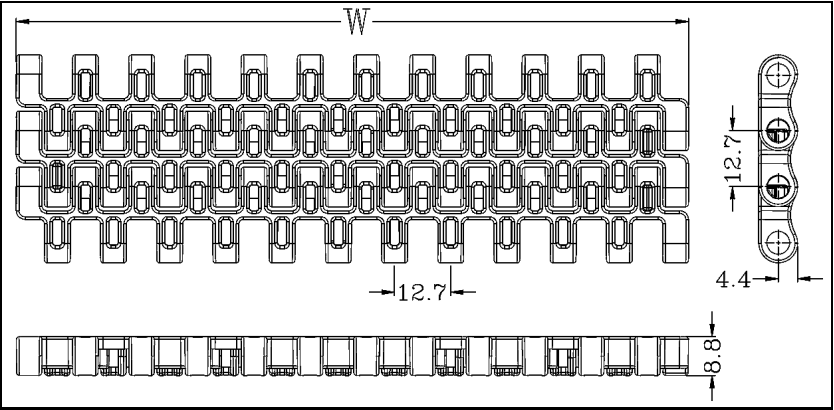

Belt data |

||||

|

Belt material |

Rod material |

Nominal tensile strength straight run N/M (21°C) |

Belt weight kg/m² |

Standard range of belt widths mm |

|

POM |

PP |

15000 |

6.30 |

76.2*n |

|

PA |

17000 |

6.50 |

||

|

PP |

PP |

7500 |

4.10 |

|

|

PE |

PE |

4500 |

4.40 |

|

|

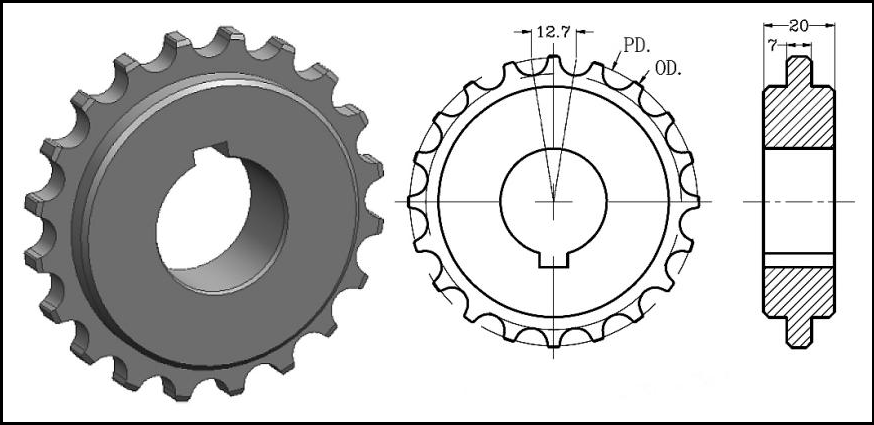

Sprocket data |

|||||||

|

Part number |

No.of Teeth |

Bore Dia.mm |

Pitch Dia. mm |

Outside Dia. mm |

Processing Technic |

Material |

|

|

Round Bore |

Square Bore |

||||||

|

SP-1251-10T |

10 |

10-18 |

41.1 |

41.5 |

Machined |

PA/PP |

|

|

SP-1251-14T |

14 |

15-25 |

57.07 |

58 |

|||

|

SP-1251-19T |

19 |

20-40 |

77.16 |

79 |

|||

|

SP-1251-20T |

20 |

20-40 |

81.18 |

82 |

|||

|

SP-1251-28T |

28 |

25-60 |

113.43 |

116.2 |

|||

|

SP-1251-38T |

38 |

30-70 |

153.79 |

157.4 |

|||

Remark:

Real belt widths are in most cases 0.1% to 0.3% smaller.

For PE material up to 750 mm (30") -2 mm to 1 mm and -0.3% to 0.1% for wider belts.

For PP material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

For POM material up to 750 mm (30") -3 mm to 0 mm and -0.4% to 0% for wider belts.

The nominal tensile strength is valid for 21 °C. The admissible tensile force depends on the operating temperature near the drive sprockets. Within the temperature range allowed, the admissible tensile force may vary from 100% to 20% of the nominal tensile strength.

Disclaimer:

Product Application Disclaimer (valid for ALL Path conveyor products and mentioned on all PDS)

This disclaimer is made by and on behalf of Path conveyor and its affiliated companies, directors, employees, agents and contractors (hereinafter collectively "Path conveyor") with respect to the products referred to herein (the "Products"). SAFETY WARNINGS SHOULD BE READ CAREFULLY AND ANY RECOMMENDED SAFETY PRECAUTIONS BE FOLLOWED STRICTLY! Please refer to the Safety Warnings herein, in the Path conveyor catalogue as well as installation and operating manuals. All indications / information as to the application, use and performance of the Products are recommendations provided with due diligence and care, but no representations or warranties of any kind are made as to their completeness, accuracy or suitability for a particular purpose. The data provided herein are based on laboratory application with small-scale test equipment, running at standard conditions, and do not necessarily match product performance in industrial use. New knowledge and experience may lead to re-assessments and modifications within a short period of time and without prior notice.

EXCEPT AS EXPLICITLY WARRANTED BY PATH CONVEYOR, WHICH WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, THE PRODUCTS ARE PROVIDED "AS IS".

Previous page

Next page

Related products

undefined

MESSAGE

* Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible